Tank Cleaning (No-man Entry)

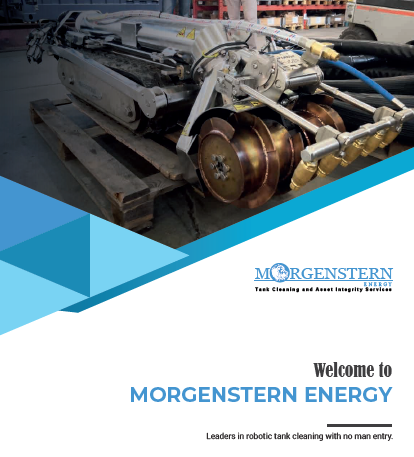

Morgenstern Energy is a leader in offering no-man entry tank cleaning services. We offer safer and faster turnaround cleaning of above-ground hazardous tanks by using our robotic no-man entry tank cleaning system. Rated for ATEX zero (0), the robotic crawler safely enters the tank via its manhole, supported by hydraulic ramps, and removes sludge from the internals of the tank. Equipped with three ATEX zero (0) cameras and LED lighting, five 450bar High pressure jetting nozzles, and one 20bar low-flow flushing nozzle the robot efficiently loosens and evacuates sludge out of the tank. The system is hydraulically controlled from an ATEX 1 rated control cabin where the operator has full visuals (aerial, front, and rear of the robot) to make a real-time decisions during cleaning operations. The system is has a fully integrated safety and shutdown system. Our Operators are trained and certified in the safe operation of the system.

FAQ

What is the pressure of the water nozzles?

There are 5x high flow jetting nozzles with maximum water jetting pressure of 450bar and 1x low flow flushing nozzle with maximum pressure of 20bar.A dedicated water pump is used.

What is the height of manhole the ramps can be used on without additional scaffolding?

600mm or less is ideal manhole height for Ramps without additional scaffold.

How do you manage tanks that require additional control umbilical length?

How do you clean ramp area inside tank?

How do you clean tanks that have internal structures/pillars?

How is the hose retrieved during withdrawal from tank?

How do you decontaminate hose/robot on exist from tank?

How fast is this method compared with conventional man-entry method?

What is the weight of the robot only?

Can the robot continue to operate if submerged in sludge?

How do you ensure safety of system?

How does the operator control the robot when it is inside the tank?

How is lighting provided inside the tank?

How does the robot access the tank?

The system comes with a hydraulic ramp which when setup outside the manhole, uses a hydraulic pump to set in the place the ramp section for the inside of the tank. Minimum manhole size for robot entry into tank is 24”.